JWFG SUS304 Hubs Jaw Coupling Flexible Shaft Coupling

Description

Series: JWFG

Product Lines: Flexible Shaft Coupling | Jaw Coupling

- Hubs: SUS304 Stainless Steel

- Spider: Polyurethane

- Wear-Resistant

- Oil Resistance

- Electrical Insulation

- Fastening method: Positioning Screw

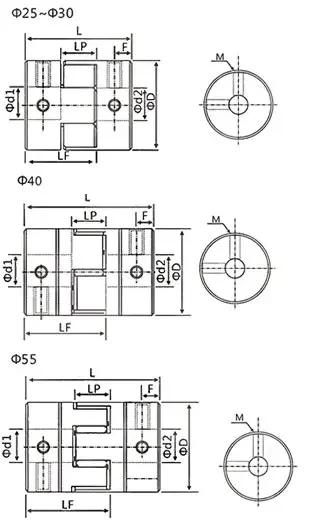

Dimensions

Model | Commonly used inside diameter size | ΦD | L | LF | LP | F | M | Tightening Torque(n.m) |

|

JWFG-25-34 | 4 5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 15 | 25 | 34 | 22.5 | 11.6 | 5.6 | M4 | 1.7 |

|

JWFG-30-35 | 5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 15 16 | 30 | 35 | 22.5 | 10.9 | 5.72 | M4 | 1.7 | |

JWFG-40-66 | 6 8 9 10 11 12 12.7 13 14 15 16 17 18 19 20 22 24 | 40 | 66 | 39.1 | 13.7 | 12.75 | M5 | 4 |

|

JWFG-55-78 | 12 12.7 13 14 15 16 17 18 19 20 22 24 25 28 30 32 | 55 | 78 | 46.2 | 16.1 | 15.5 | M6 | 7 |

|

Exploded Diagram

Specifications

Model | Rated Torque(N.m) | Eccentricity allowed(mm) | Angular Deviation(∠°) | Axial Deviation(mm) | Rotating Speed(RPM) | Torsional Stiffness(N.m/rad) | Moment of Inertia(N.m) | Hubs Material | Spider Material | Finish | Weight (g) |

JWFG-25-34 | 9 | 0.02 | 1 | ±0.60 | 16000 | 65 | 5.0 x 10-6 | SUS304 Stainless Steel | Polyurethane | Polished | 75 |

JWFG-30-35 | 9.8 | 0.02 | 1 | ±0.60 | 12000 | 72 | 5.5 x 10-6 | 114 | |||

JWFG-40-66 | 48 | 0.02 | 1 | ±0.80 | 10000 | 550 | 3.8 x 10-5 | 350 | |||

JWFG-55-78 | 69 | 0.02 | 1 | ±0.80 | 8000 | 1500 | 1.5 x 10-3 | 778 |