China CNC Machining Services

CNC Machining Services

What is CNC Machining?

Why choose CNC Machining?

Advantages of Jinwang’s Services

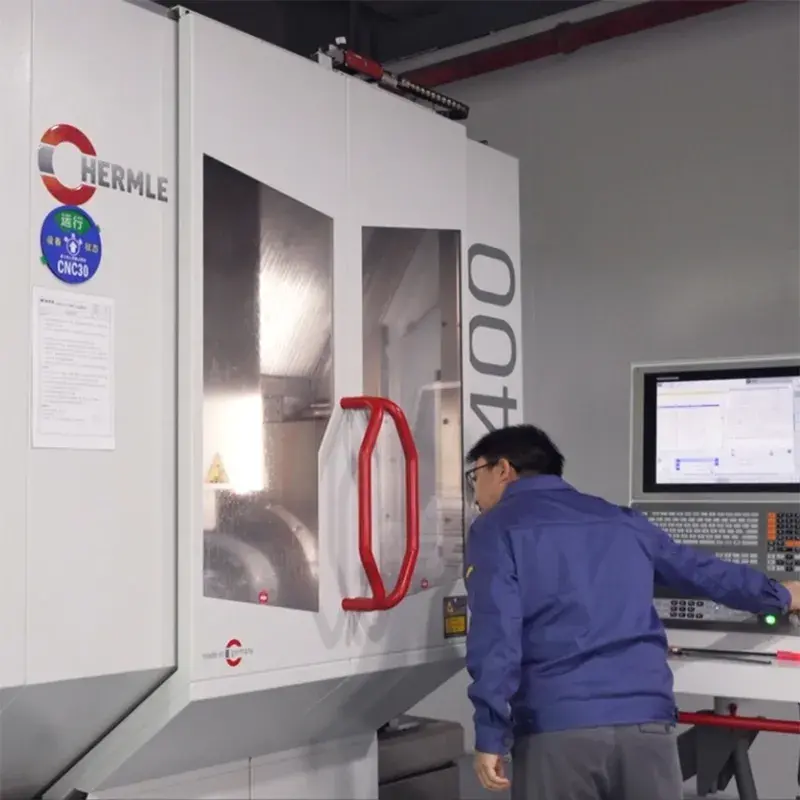

• Advanced equipment

Jinwang is a top CNC product manufacturer in China. For more than 20 years, Jinwang has continuously updated its production and inspection equipment. Currently, Jinwang has CNC turning centers, milling centers, three-axis/four-axis/five-axis machining centers, cylindrical grinders, There are more than 300 sets of production equipment and testing equipment such as centerless grinding machines and gear hobbing machines. We only use high-quality domestic or imported equipment to produce customer orders.

• Competitive prices in the industry

Jinwang’s competitive prices are the result of the company’s efficient production process.

• Wide selection of materials

Jinwang’s wide selection of materials ensures that there is a material to suit every need. The company offers an extensive range of metals, plastics, and composites, as well as a variety of finishes. This means that no matter what the project, Jinwang can provide the perfect solution.

• The helpful customer service

Jinwang’s customer service is excellent and efficient. They are always willing to help customers with any problems they may have. The staff is knowledgeable and friendly, and they make sure that all customers are satisfied with their experience. Jinwang’s customer service is the best in the industry, and they are always looking for ways to improve.

• Quality assurance

Jinwang has a strong quality assurance program in place to make sure our customers are always happy with our products and services. We have a team of experienced quality assurance professionals who work diligently to test and improve our products and services. We also offer a 100% satisfaction guarantee to our customers so they can be confident they’re making the best decision when they choose Jinwang.

• Rapid Manufacturing and Delivery

Jinwang’s experience and reputation make it a trusted partner for businesses in need of rapid manufacturing and delivery services. The company s ability to meet tight deadlines makes it an invaluable asset for businesses that require fast turnaround times.

Our CNC Machining Services & Industries We Serve

CNC Milling

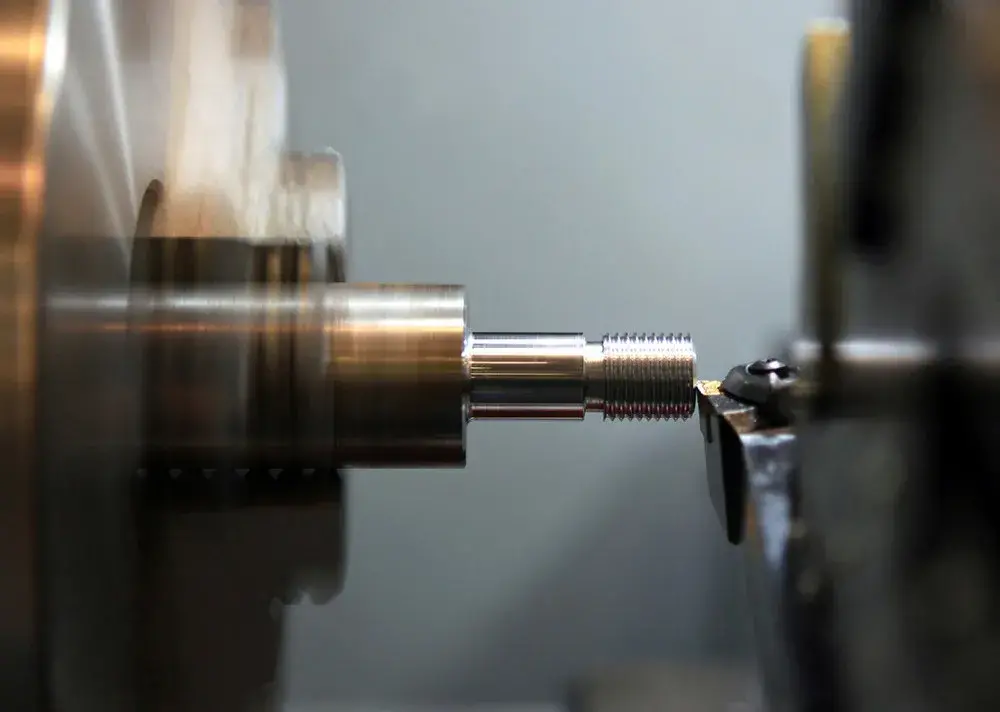

CNC Turning

Gear Hobbing

CNC machining parts are used in electrical tools because of their ability to create complex shapes with a high degree of accuracy. This makes them ideal for creating parts for electrical tools that need to be precise.

CNC machining parts are used in Automotive. In the automotive industry, CNC machining is used to create a variety of parts, including engine and transmission parts, suspension components, and wheels.

CNC machining allows for the creation of parts with a high degree of precision and repeatability.

When used in conjunction with other manufacturing processes, such as stamping or injection molding, CNC machined parts can be used to create a wide variety of automotive components.

CNC machining parts are used in Robotics Automation. They are used to create the different parts of robots that are needed for automation. CNC machining is a process where a machine is controlled by a computer to create precise parts.

CNC machining parts are used in a variety of electronics applications. From simple to complex parts, CNC machining can create the perfect part for your project.

CNC machining parts are used in Laser Machine.

Laser machines are a type of CNC machine. Laser machines use a laser to cut or engrave material. Laser machines can be used to cut or engrave metal, wood, plastic, and other materials.

CNC machining parts are an important part of the laser machine. The laser machine would not be able to function without them.