Content Navigator

- What is the Gear Measuring Instrument?

- What are the Basic Items of Gear Accuracy Measurement?

- What are the Precautions for the Operation of Gear Measuring Instrument?

What is the Gear Measuring Instrument?

The gear measuring instrument is an industrial equipment used to measure the involute tooth profile error, helical tooth profile error, helix deviation, tooth pitch deviation, radial runout of cylindrical gears or gear cutters, and gear shaving cutters, It is a simple and practical high-precision gear measuring instrument for the tooth profile deviation, tooth pitch deviation and radial runout of the gear shaper cutter. Widely used in factory measuring room or workshop inspection station.

Measurement Classification of Gear Measuring Instrument?

Analytical Testing

Analytical testing is commonly known as single-item testing, and generally includes gear tooth shape and orientation, common normal and variation, radial runout, base joint deviation, weekly joint cumulative error, etc. This detection method requires special measuring tools and detection instruments, so some small processing enterprises cannot detect it (mainly for the detection of tooth shape and tooth direction, a gear measuring instrument is required)

Functional Testing

Functional testing is also called comprehensive testing. This requires a measuring instrument, which is much cheaper than a tooth shape and direction tester, and is more suitable for mass testing with low precision requirements. Use the standard gear with known precision (the general precision is around 4th grade and 5th grade) to detect the gear under test, because the precision of the standard gear is higher than that of the gear under test, so the detected deviation is regarded as the deviation of the part under test. Processing errors.

What are the Basic Items of Gear Accuracy Measurement?

Basic items of gear accuracy measurement

The gears milled on the milling machine are spur gears, helical spur gears, straight racks, helical racks and straight bevel gears. Gear accuracy measurement mainly includes the following items:

- public normal length measurement. Common normal line measurement is an effective measurement method to ensure the accuracy of gear backlash. It has the characteristics of simple and accurate measurement in gear measurement, and is not limited by star reference. It is one of the most commonly used methods for gear star measurement.

- degree circular chord tooth thickness measuring star. The indexing national chord tooth thickness measurement method is a single-tooth measurement method that ensures the accuracy of the tooth side gap. It is convenient to apply in actual production. Its disadvantage is that the diameter error of the addendum circle of the gear will affect the measurement accuracy of the chord tooth height.

- Fixed chord tooth thickness and chord tooth height measurement.Fixed chord tooth thickness and chord tooth height are only related to the modulus and pressure angle of the gear.

- Measurement of the radial circular runout of the ring gear. The radial circular runout of the gear is the maximum variation of the probe relative to the gear axis when the probe is in double-sided contact with the high center of the tooth in the tooth groove or on the gear teeth within the range of one revolution of the gear.

- Measuring the accumulative error of tooth pitch. Measure the error value of each pitch to the initial pitch.

- Tooth profile measurement. Measuring the shape error of gear tooth root, tooth flank and addendum parts.

- Tooth direction measurement. Measure the error between the actual tooth direction and the designed tooth direction.

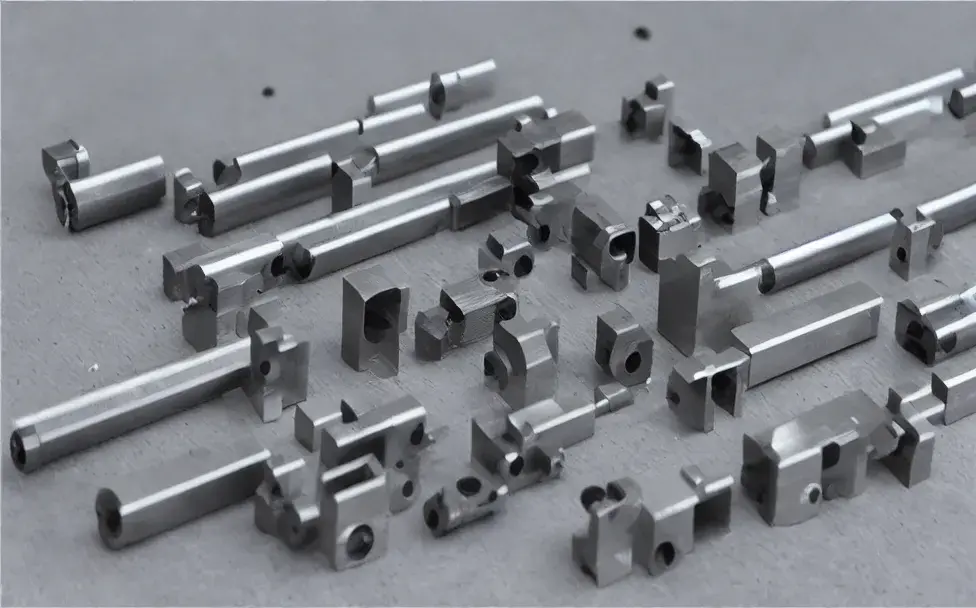

Commonly Used Gear Measuring Instruments

- Measuring instruments for measuring the length of the common normal line include the common normal line micrometer, the common normal line indicating caliper, and the common normal line lever micrometer. Ordinary vernier cards and special calipers can also be used, and the universal tooth measuring instrument can also be used to measure the length of the common normal line.

- The star measuring instruments for measuring the tooth thickness of graduated circular chords and fixed chords of gears include tooth thickness vernier calipers, optical tooth measuring calipers and various tooth thickness clamps (use open end and stop end to control the dimensional accuracy of tooth thickness).

- The measuring instrument for measuring the radial circular runout error of gears usually uses a gear pitch radial circular runout tester, and a universal gear measuring instrument can also be used.

- The measuring instrument for measuring gear tooth pitch error, ring gear radial circular runout, common normal line length, tooth thickness variation, etc., generally uses a universal gear measuring instrument.

What are the Precautions for the Operation of Gear Measuring Instrument?

- Every time you turn on the measuring instrument, you need to perform system reset (F4) and side head calibration to check whether the system reset movement is normal

- When turning off the measuring instrument, first turn off the servo (red emergency stop button), then turn off the main power switch, and finally turn off the voltage regulator

- When opening the measurement software to input parameters, pay attention that the true diameter of the side head must be less than or equal to the modulus, and the left-handed helix angle is negative, and the right-handed is positive

- After the parameter input is complete, click “Standard Calculation of Tooth Profile” and “Standard Calculation of Tooth Direction”, and then “Start Measurement”

- Manually enter the height of the side head, note: (1) the height of the side head of the gear is about 5 mm above the lower end of the tooth width; (2) the height of the side head of the gear shaper is about 5 mm below the upper end of the tooth width; ( 3) The head alignment height of the hob is at the middle height of the left side of the first tooth; (4) The head alignment height of the inner tooth is at the upper middle of the keyway; (5) The head alignment height of the shaving cutter is at the left side of the bottom tooth side middle position

- Pay attention to the measurement of the gear shaper cutter. When the side head is calibrated up and down, the side head on the operation panel of the measuring instrument cannot be used for calibration, and only “F6 up and down calibration” on the computer can be used.

- For internal tooth measurement, pay attention to use the rotating handle on the control panel when rotating the C-axis

- When rotating the side head, please note that the side head can only be in two positions of 0 degrees and 90 degrees, and the side head cannot be rotated to other positions

In the next article, we will continue to explain the measurement of gear meshing, from which we can learn about the comprehensive measurement method of meshing and rolling between standard gears and the gears you produce.

About Gear Mesh click here!!!