This article will introduce in detail what is gear meshing, the type of gear meshing, how to detect it, and the failure mode of gear meshing, etc.

Content Navigator

- What is Gear Mesh?

- Types of Gear Meshes

- Conditions for Gear Meshing

- Influencing Factors of Gear Meshing Failure

- Gear Mesh Testing Instrument

What is Gear Mesh?

Gear meshing is the degree of engagement between two gears, and refers to a transmission relationship between two mechanical parts, called meshing transmission. Gear meshing transmission has the characteristics of wide adaptability, high transmission efficiency, long working life, stable transmission, high reliability, constant instantaneous transmission ratio, and two-axis transmission that can realize various position requirements. It is widely used in modern mechanical transmission. very broad. It consists of driving gear, driven gear and frame. Through the meshing action of the gears, the movement and power of the driving wheel (shaft) are transmitted to the driven (shaft), and the required speed and torque are obtained.

Types of Gear Meshes

Gear meshing is a critical component of the operation of many machines, from automotive transmissions to industrial machinery. According to different classification methods, there are many types of gear meshing transmission.

- According to whether the angular velocity of a pair of gear meshing transmission is constant, it can be divided into non-circular gear meshing transmission and circular gear meshing transmission.

- According to the shape of gear teeth, it can be divided into involute gear meshing transmission, arc gear meshing transmission, cycloid gear meshing transmission, etc.

- According to the shape of the gear teeth, it can be divided into straight tooth meshing transmission, helical tooth meshing transmission, and curved tooth meshing transmission.

- According to the hardness of the tooth surface, it can be divided into soft tooth surface gear (<350HBS) meshing transmission and hard tooth surface gear (>350HBS) meshing transmission.

- According to the different working conditions of gears, it can be divided into open gear meshing transmission and closed gear meshing transmission. The former has no closed gear box, the gear teeth are exposed, easy to be affected by dust, and the lubrication conditions are poor; the latter has a closed gear box.

Conditions for Gear Meshing

From the principle of meshing, for any gear, whether it is an involute gear or a double-arc gear, if they mesh correctly, the meshing condition is met: the normal vector at their contact point is perpendicular to the relative motion speed between them, then they are correctly meshed.

However, different types of meshing gears have different meshing conditions. According to the classification of meshing gears, the meshing conditions are mainly as follows.

1.Spur gears:The modulus of the two gears must be equal, and the tooth profile angles on the pitch circles of the two gears must be equal.

2.Helical cylindrical gear:The normal modulus of the two gears is equal, the tooth profile angle is equal, the helix angle is equal and the helix direction is opposite.

3.Straight bevel gear:

- The big end modulus and tooth profile angle of the two gears are equal respectively.

- The modules of the two gears must be equal, and the tooth profile angles on the pitch circles of the two gears must be equal. The normal modulus of the two gears is equal, the tooth profile angle is equal, the helix angle is equal and the helix direction is opposite. The big end modulus and tooth profile angle of the two gears are equal respectively.

- Due to the standardization of gear machining tools, the gear meshing conditions must be equal to the modulus and pressure angle. The condition of continuous meshing of gears is that the degree of contact must be greater than 1.

Influencing Factors of Gear Meshing Failure

The failure of gear meshing transmission mainly refers to the failure of gear teeth. Due to the different application occasions, working conditions, gear materials and heat treatment processes of gear meshing transmission, there are many failure modes, but there are five common failure modes as follows.

1.The gear teeth are broken

The gear under load in the operation project is like a cantilever beam. When the root of the pulsed periodic stress exceeds the fatigue limit of the gear material, cracks will be generated at the root and gradually expand. When the remaining part cannot bear the transmission load, it will occur. Broken teeth phenomenon. Gears may also be broken due to severe impact, partial load and uneven material during work.

2.Gear surface fatigue pitting

When the teeth of two meshing gears are in contact, the action force and reaction force between the tooth surfaces cause contact stress on the two working surfaces. Since the position of the meshing point changes and the gears do periodic motion, the contact stress is Varies according to the pulsation cycle. Under the action of this alternating contact stress on the tooth surface for a long time, small cracks will appear at the knife marks on the tooth surface. As time goes by, this crack will gradually expand laterally on the surface layer, and after the crack forms a ring, the wheel The surface of the tooth produces a small area of spalling to form some fatigue shallow pits.

3.Gear surface wear

For open gear transmission or closed gear transmission containing unclean lubricating oil, due to the relative sliding between the meshing tooth surfaces, some hard abrasive particles enter the friction surface, thereby changing the tooth profile and increasing the backlash. So that the gear is excessively thinned and the teeth are broken. Under normal circumstances, only when the lubricating oil is mixed with abrasive particles, it will cause abrasive wear on the tooth surface during operation.

4.Gear surface gluing

For high-speed and heavy-duty gear transmission, due to the large friction between the tooth surfaces and the high relative speed, the temperature of the meshing area is too high. Once the lubrication conditions are poor, the oil film between the tooth surfaces will disappear, making the metal of the two teeth The surfaces are in direct contact so that mutual bonding occurs. When the two tooth surfaces continue to move relative to each other, the harder tooth surface will tear off part of the material on the softer tooth surface along the sliding direction to form grooves.

5.Plastic deformation of gear surface

Under impact load or heavy load, the tooth surface is prone to local plastic deformation, thus deforming the curved surface of the involute tooth profile.

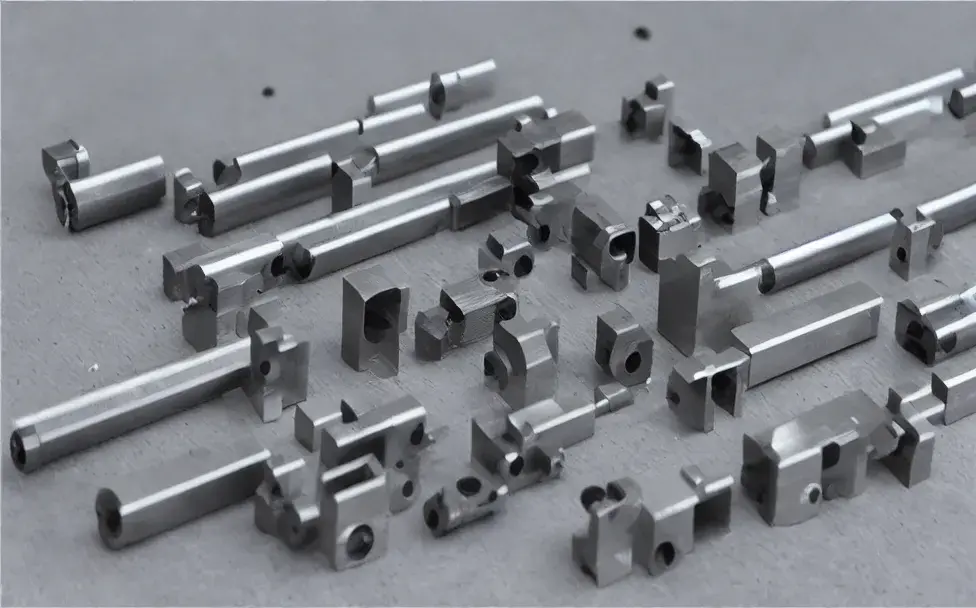

Gear Mesh Testing Instrument

Gear checker, an instrument for checking gear errors. It is divided into two types: comprehensive inspection instrument and single inspection instrument. The comprehensive inspection instrument is composed of a single-sided meshing gear inspection instrument and a double-sided meshing gear inspection instrument, which can inspect comprehensive errors in gear transmission. The single-sided meshing gear tester can check the transmission accuracy of the gear; the double-sided meshing gear tester can check the center distance change of a pair of gears in the transmission and other parameters. Single-item testers generally can only test individual parameters of gears. For example, the tooth shape checker for checking the tooth shape, the tooth direction checker for checking the contact condition, the base joint checker for checking the pitch of the base circle, and the circumferential joint checker for checking the pitch of the indexing circle, etc. The new gear overall error measuring instrument can automatically decompose each individual error.

1.Gear single-sided meshing tester

Single gear meshing tester, referred to as single meshing instrument, is used to measure tangential comprehensive error and so on. The single mesh meter can be divided into grating type, magnetic grid type and inertial type. When the measuring gear drives the gear to be tested to rotate, the rotation angle error caused by the combination of individual errors such as the pitch, tooth shape, tooth orientation, and radial runout of the gear under test passes through the circular grating sensor installed coaxially with the gear under test. converted into an electrical signal output. This electrical signal is compared with the electrical signal output by the circular grating sensor installed coaxially with the measuring gear after being amplified, sorted, and frequency-divided, and then the error curve is recorded by the recorder. This kind of gear inspection instrument is generally used to measure gears with a precision of 5 to 6, and it can reach.

2.Gear double-sided meshing tester

Gear double-sided meshing tester, referred to as the double-mesh tester, is used to measure the radial comprehensive error and the change of the center distance of the gear pair, etc. Under the action of the spring force, the measuring gear is engaged with the measured gear on both sides, and the single error such as the radial runout of the ring gear and tooth profile error of the latter is comprehensively reflected as the radial variation parallel to the guide rail. The value is indicated by the dial indicator, or the error curve is recorded by the recorder. The maximum variation in one tooth rotation and one tooth rotation of the tested gear is the radial comprehensive error and the radial comprehensive error of one tooth respectively; the large variation obtained from the paired measurement of a pair of tested gears is the change in the center distance of the gear pair. The double-gear instrument has a simple structure and is widely used in mass production to test gears with precision below grade 7.

About Gear Measurement Method click here!!!