Content Navigator

- What are the Main Types of Calipers?

- What are the main functions and features of calipers?

- Uses of a Caliper

- Precautions and Maintenance for Using Calipers

What are the Main Types of Calipers?

There are mainly three types of calipers: vernier calipers, dial calipers and electronic digital calipers.

- Vernier caliper. A ruler-shaped portable general-purpose length measuring tool that uses the vernier principle to subdivide the readings. It is mainly used to measure inner diameter, outer diameter, steps and depth. When measuring, the integer part of the value is read from the main scale, and the decimal part is read from the vernier scale. The principle of the vernier is to use the difference between the distance between the engraved lines on the main scale (referred to as the line distance) and the line distance on the vernier scale to read the fractional part. There are three minimum reading values of 0.02mm, 0.05mm and 0.01mm.

- Caliper with watch. It is a large-sized portable length measuring tool that takes the tooth pitch of precision racks and gears as the known length, and uses the indicator table with corresponding graduations as the magnification, subdivision and indication parts. Caliper with table can solve the reading error problem of vernier caliper. The common minimum reading values are 0.01mm and 0.02mm.

- Electronic digital calipers. It is a length measuring tool that uses measuring systems such as capacitive grids and magnetic grids to digitally display the measured value. The commonly used resolution is 0.01mm, and the allowable error is ±0.03mm/150mm. There are also high-precision digital calipers with a resolution of 0.005mm, and the allowable error is ±0.015mm/150mm. There is also a multi-purpose digital display micrometer caliper with a resolution of 0.001mm (this is the national patent of Anyi Measuring Tool, only they can produce it), and the allowable error is ±0.005mm/50mm. Due to the intuitive and clear readings, the measurement efficiency is high.

In addition, there are various non-standard calipers, such as hook depth calipers to measure the depth of grooves, tooth thickness calipers to measure the thickness of gears, height calipers to measure the height of objects, and weld calipers (weld gauges) to measure welding quality Wait.

Special-purpose calipers: pointed claw type, irregular and unknown size measurement Offset type, measurement of position dimensions in unequal height areas Depth type, depth measurement Thin slice type, narrow groove diameter measurement.

What are the main functions and features of calipers?

The Main Functions:

- Outer diameter measurement (lower/outer jaws)

- Inner diameter measurement (upper/inner measuring jaw)

- Step measurement (left head)

- Depth measurement (tail depth needle)

Main Feature:

- The main scale and jaws of the light Digimatic caliper are made of CFRP (carbon fiber reinforced plastic).

- Durable and easy to operate.

- The scope of application can be expanded through options.

- The measured value of the inner diameter can be read directly from the LCD screen (the offset value can be conveniently set by pressing the offset key).

- The desired starting point can be set through the preset function.

- With SPC data output.

- The special model with ceramic jaws is suitable for measuring magnetic products; the caliper has a simple and basic design; the caliper can measure outer diameter, inner diameter, depth and step difference; the vernier surface angle of the caliper is small (14°), Easy to read; caliper slides are fitted with locking screws; calipers are available with carbide-tipped jaws.

Uses of a Caliper

A caliper measuring tool is a versatile device used in many industries to accurately measure the thickness or diameter of an object. It consists of two adjustable arms that are connected by a central bar and spring-loaded plunger. The arms can be adjusted to take measurements from different angles, depending on the type of measurement required.

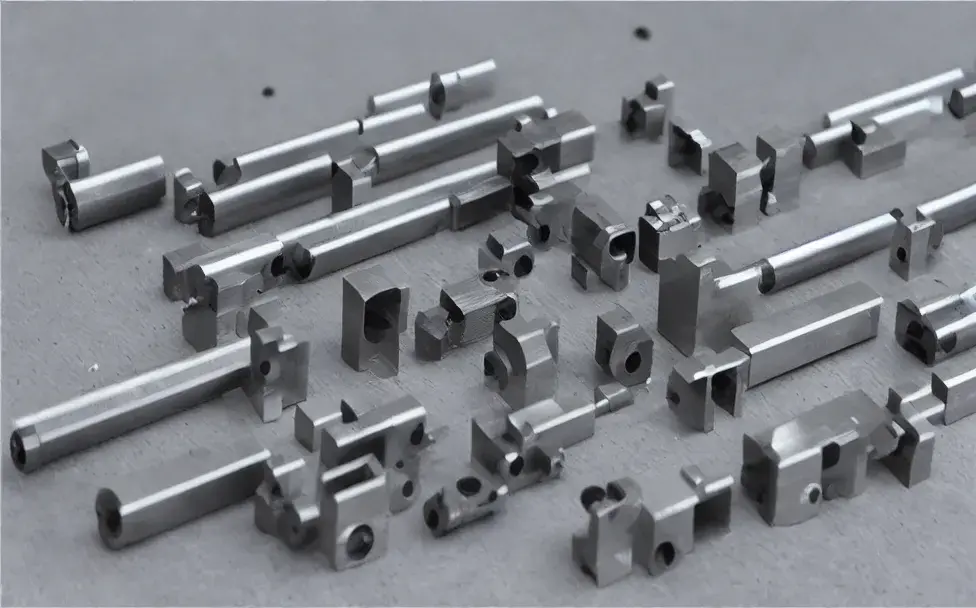

Caliper tools come in various sizes and shapes, including digital versions for even more precise readings. They are commonly found in workshops, machine shops, laboratories and other industrial settings where precision measurements are needed. Common uses for calipers include measuring the diameter of a hole or shaft, determining inner/outer diameters when working with pipes or tubing, checking wall thicknesses of components such as engine blocks and cylinders, and gauging depths on molds or other machined parts.

Precautions and Maintenance for Using Calipers

Precautions

- The vernier caliper is a relatively precise measuring tool. It should be handled with care and should not be bumped or dropped to the ground. Do not use it to measure rough objects, so as not to damage the measuring claws. When not in use, it should be placed in a dry place to prevent corrosion.

- When measuring, the fastening screw should be loosened first, and the cursor should not be moved with excessive force. The contact between the two measuring claws and the object to be tested should not be too tight. The clamped object cannot be moved in the measuring jaw.

- When reading, the line of sight should be perpendicular to the ruler surface. If the reading needs to be fixed, the vernier can be fixed on the scale body with fastening screws to prevent sliding.

- In the actual measurement, the same length should be measured several times, and the average value should be taken to eliminate accidents.

Maintenance

- Operation inspection Before using it every day, check whether the zero scale of the vernier caliper is aligned, whether the scale is clearly visible, and whether the movement is smooth. If so, the caliper can be used normally. Otherwise, the caliper needs to be repaired or replaced with a new one. Caliper, and according to the instrument failure treatment method in the operation inspection regulations.

- Precautions: After using the vernier caliper, wipe it clean with cotton yarn. When not in use for a long time, rub it with butter or engine oil, close the two measuring claws and tighten the fastening screws, put it into the caliper box and cover it, and avoid placing it in an environment with dust, humidity, supercooling and superheating, and acid-base vapor.