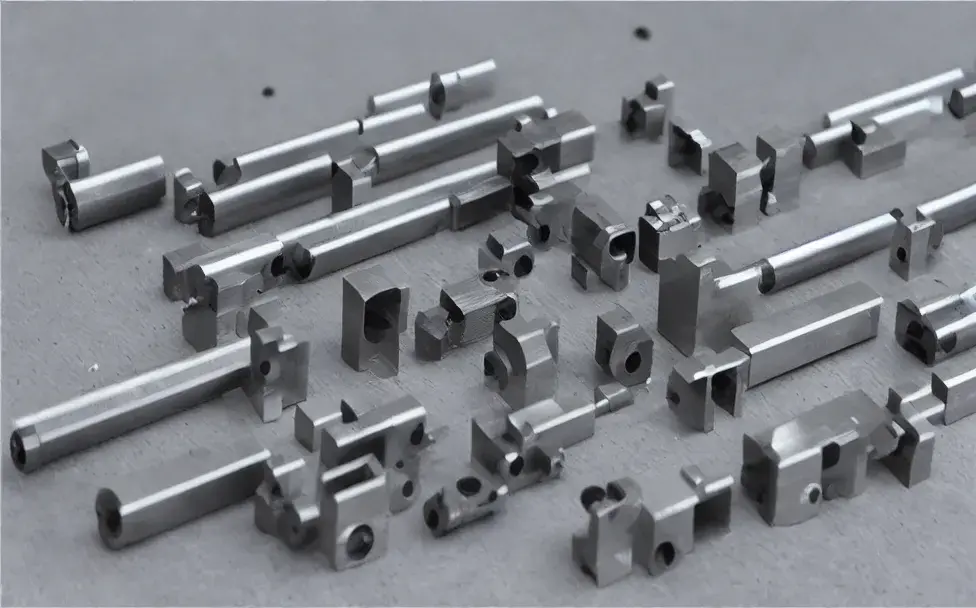

What is a Keyway Cutter?

A keyway cutter is a specialized tool that is used to cut a slot or groove, known as a keyway, into a shaft or hub. These cutters come in a range of sizes and shapes, with the most common being rectangular or square. Keyway cutters are typically made from high-speed steel or carbide, which provides durability and ensures a long tool life.

What does a Keyway Cutter do?

Keyway cutters are used to create keyways that are critical to the functioning of mechanical systems. The keyway allows a key, or a small piece of metal, to fit into the slot, creating a secure connection between the shaft and the hub. This connection is crucial for transmitting torque and power between the two components.

How to Use a Keyway Cutter?

Using a keyway cutter requires skill and precision to ensure a high-quality cut that meets the required specifications. Here are the steps to follow when using a keyway cutter:

Step 1: Prepare the Shaft or Hub

Before using the keyway cutter, it is important to prepare the shaft or hub to ensure a clean cut. This involves removing any rust, debris, or oil from the surface and ensuring that it is properly supported in the milling machine.

Step 2: Set up the Cutter

The next step is to set up the keyway cutter in the cnc milling machine. This involves installing the cutter in the appropriate collet or chuck and adjusting the cutting depth and feed rate. It is important to ensure that the cutter is aligned correctly with the workpiece to avoid any errors.

Step 3: Make the Cut

Once the cutter is set up, it is time to mill. This involves slowly moving the cutter along the length of the workpiece, taking care to maintain a constant cutting depth and feed rate. The process should be repeated until the desired depth and width of the keyway is achieved.

Step 4: Clean up

After the cut is complete, it is important to clean up the workpiece to remove any debris or chips that may have accumulated during the cutting process. This will ensure that the keyway fits correctly and operates smoothly.

In conclusion, a keyway cutter is an essential tool in a range of industries, including manufacturing and repair. By following the steps outlined in this article, you can use a keyway cutter with skill and precision to create high-quality keyways that ensure the smooth operation of mechanical systems. In the next article, we will explain in detail several other processing methods of the keyway.