Titanium is a highly durable and lightweight metal that is often used in aerospace, medical, and military applications. It is a naturally occurring element that was first discovered in the 18th century. The metal has a low density and high strength-to-weight ratio, which makes it an ideal material for many engineering applications.

Titanium is highly resistant to corrosion, and is often used in applications where the metal will be exposed to harsh environments, such as seawater. It is also biocompatible, which means that it can be used in medical implants without causing adverse reactions in the body.

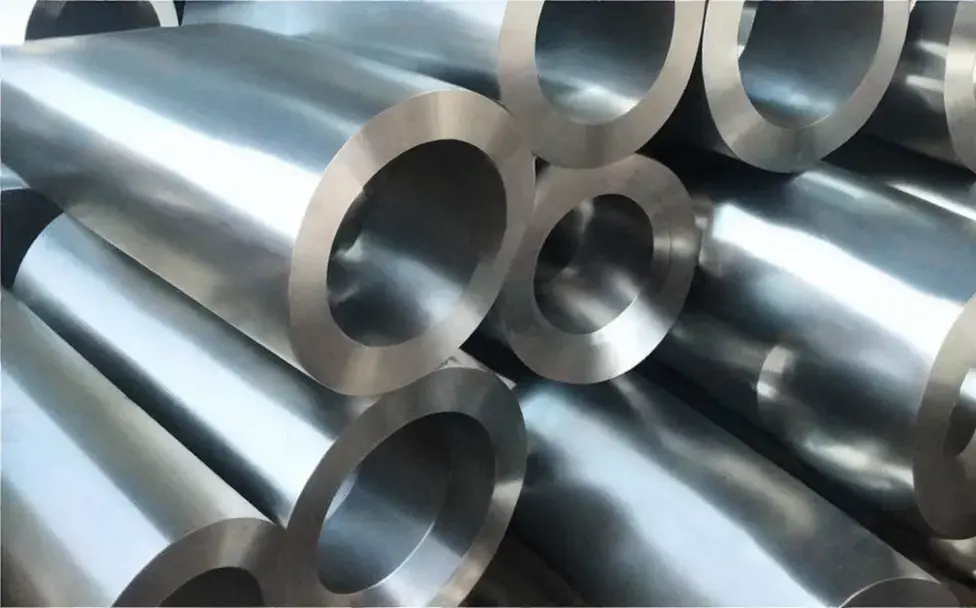

Steel is an alloy of iron and other elements, such as carbon and manganese. It is one of the most widely used metals in the world, and is used in a variety of applications, such as construction, automotive manufacturing, and consumer goods. The strength, durability, and versatility of steel make it an essential material for modern society.

Differences Between Titanium and Stainless Steel

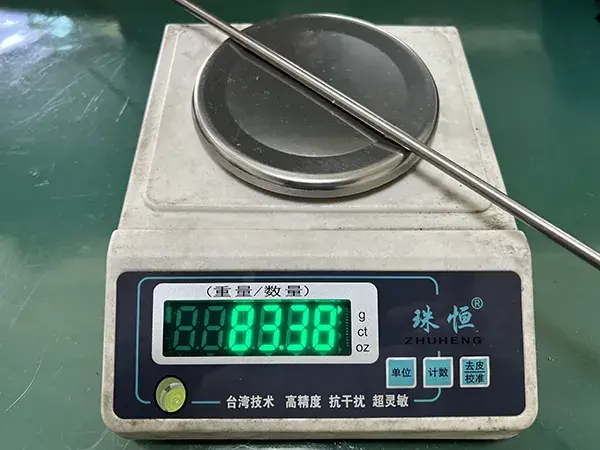

There are several key differences between titanium and steel. One of the most notable differences is their weight. Titanium is significantly lighter than steel, which makes it ideal for applications where weight is a concern, such as in the aerospace industry.

Another difference between the two metals is their cost. Titanium is generally more expensive than steel, due to its scarcity and the difficulty of extracting and processing the metal. Steel, on the other hand, is relatively inexpensive and widely available.

Physical Properties of Titanium and Steel

Titanium:

- Low density

- High strength-to-weight ratio

- High melting point of 1,668 degrees Celsius

- Highly ductile and easily formed

- Highly resistant to corrosion

- Biocompatible, suitable for medical implants

Steel:

- High strength and durability

- Widely available and relatively inexpensive

- Versatile, with many different types for different applications

- Lower melting point than titanium, at around 1,370 degrees Celsius

- Ductile, but to a lesser degree than titanium

- Different types of steel can have varying degrees of corrosion resistance

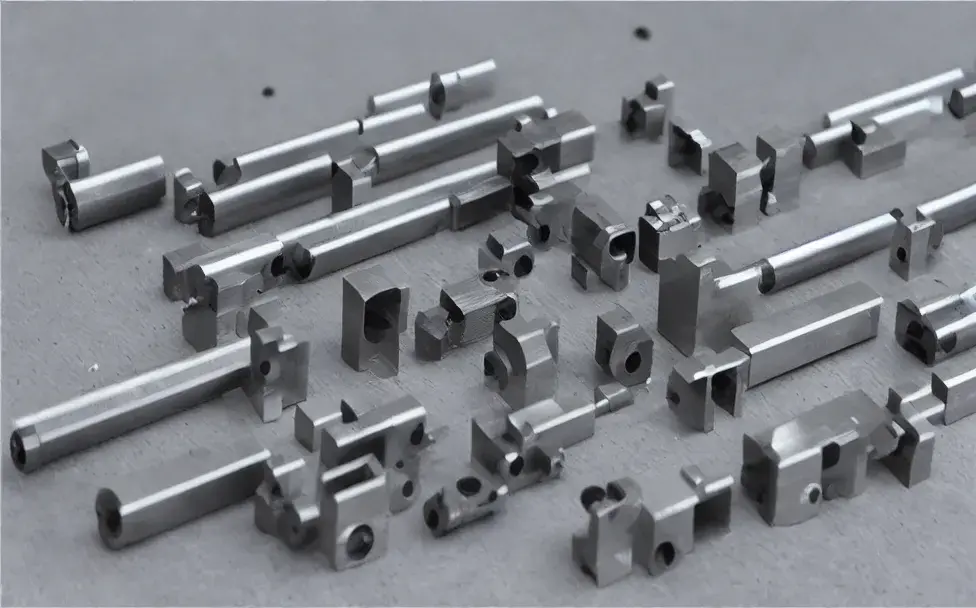

CNC Machining of Titanium and Steel: Important Considerations

When it comes to manufacturing, both titanium and steel can be used in CNC machining processes. CNC machining is a process that involves the use of computer-controlled machines to remove material from a workpiece. This process is often used to create complex parts and components with tight tolerances.

While both titanium and steel can be machined using CNC machines, there are some differences to keep in mind. For example, titanium has a tendency to work harden, which means that it becomes harder and more difficult to machine as it is worked. To prevent this, it is important to use sharp tools and avoid high cutting speeds.

Steel, on the other hand, can be more forgiving in terms of machining. It is a softer metal than titanium and is less likely to work harden. However, different types of steel can have different machinability properties, so it is important to choose the right steel alloy for the application and use the appropriate cutting tools and techniques.

Titanium and steel are two of the most important metals in modern manufacturing. They each have their own unique properties and characteristics, which make them well-suited for specific applications. While titanium is lighter, stronger, and more corrosion-resistant than steel, it is also more expensive. Steel, on the other hand, is widely available and relatively inexpensive, and is still used in a wide range of applications due to its strength and durability.

It’s worth noting that both titanium and steel are commonly used in CNC machining, a manufacturing process that involves the use of computer-controlled machines to create precise and complex parts. CNC machined is a popular manufacturing method for a wide range of industries, including aerospace, automotive, and medical.