18:1

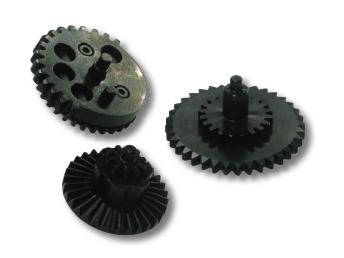

Description

NEED MORE DISCOUNTS ?

WHY USE 40Cr MATERIA

CNC GEAR

PRECISION GEAR

AIRSOFT GEAR SET

PRECISION

CNC TURNING

HOBBING GEAR

CNC MILLING

STABILITY & RELIABILITY

The gear shaft and the gear piece adopt an interference fit of 0.05mm, and the purpose of tight connection is achieved through the press-fitting method. In actual production, only by strictly controlling the tolerance can the quality, stability and reliability of the gear connection be guaranteed. Too large or too small will affect the service life of the gear in high-speed operation, and seriously cause the gear shaft and the gear to separate.

For example:

HARDNESS & DEMAGNETIZING

Hardness: HRC45-50

Hardness: HRC45-50

The 40Cr material itself has its own magnetism. In order not to affect the accuracy and service life, and to avoid the adsorption of tiny metal powder on the gear, we have done demagnetization treatment before leaving the factory. The following is the real shot of hardness test and demagnetization

OUR FACTORY

Processing Technology

Order Process

If you are interested in our product types/services, welcome to customize.

- Provide your drawings/samples

- Decomposition product process

- provide pricing

- Provide production control solutions

- Order raw materials

- start production

- full size inspection

- Delivery of your goods with inspection form

Read More Details Click Here!