What is a single axis CNC lathe?

Single-axis Numerically Controlled (NC) lathes are an essential tool in modern manufacturing. These machines are designed to produce high-precision parts with great accuracy and efficiency. Single-axis NC lathes are widely used in industries such as automotive, aerospace, and medical devices, where accuracy and consistency are essential.

Single-axis NC lathes have a single spindle that rotates the workpiece, while a cutting tool is moved along the X-axis. This type of machine is typically used for simple turning operations, such as boring, drilling, and tapping, and is ideal for small- to medium-sized parts that require only a few cuts. The single-axis NC lathe is a cost-effective solution for small-scale operations and hobbyists.

Advantages and Disadvantages of single axis CNC lathes

Advantages:

- Cost-effective: Single-axis NC lathes are typically less expensive than multi-axis machines, making them a popular choice for small-scale operations and hobbyists.

- Simple to operate: Single-axis NC lathes have only one axis of motion, making them easier to operate and maintain compared to multi-axis machines.

- Accurate results: Single-axis NC lathes are capable of producing parts with tight tolerances, resulting in consistent and accurate parts.

Disadvantages:

- Limited capabilities: Single-axis NC lathes are limited in their ability to produce complex parts with multiple cuts, as they have only one axis of motion.

- Reduced efficiency: Single-axis NC lathes can be less efficient than multi-axis machines for complex parts, as multiple setups may be required.

In conclusion, single-axis NC lathes are a cost-effective solution for small-scale operations and hobbyists. These machines are simple to operate, maintain, and produce high-precision parts with great accuracy. If you’re in need of a machine for simple turning operations, consider a single-axis NC lathe as a viable option.

What is a multi-axis CNC lathe?

CNC (computer numerical control) technology has revolutionized the world of manufacturing, providing greater precision and automation to the production process. Among the various types of CNC machines, multi-axis CNC lathes have become increasingly popular due to their versatility and ability to handle complex machining operations.

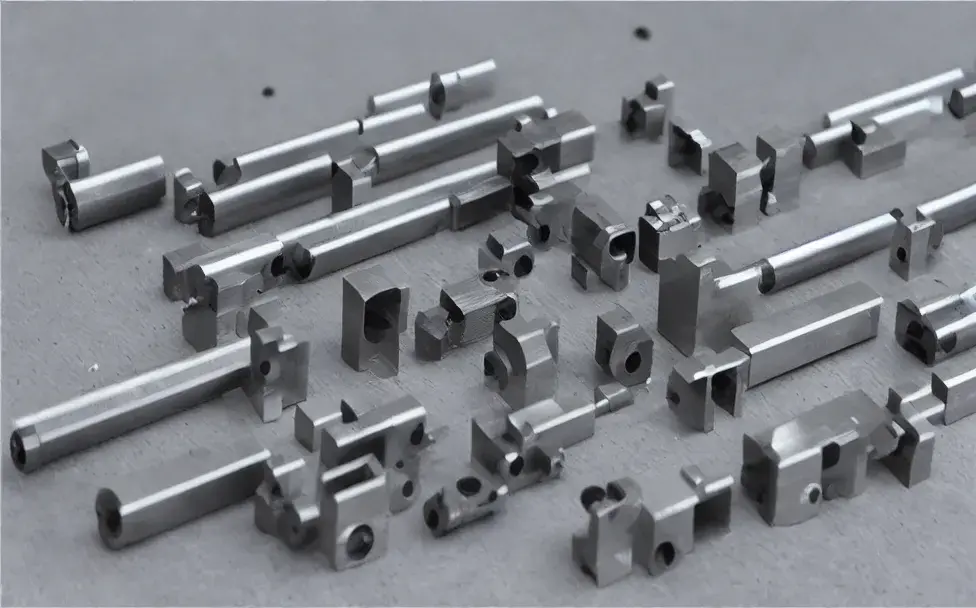

A multi-axis CNC lathe typically has two or more axes, allowing it to move the cutting tool in multiple directions, which enables the machine to perform multiple operations in one setup. This eliminates the need for multiple setups, reducing the time and cost of production. Moreover, the use of multiple axes allows for more complex machining operations, such as contouring, drilling, tapping, and milling.

Advantages and Disadvantages of multi-axis CNC lathe

Advantages:

- Increased capabilities: Multi-axis NC lathes have multiple axes of motion, allowing for more complex cuts and shapes to be produced, resulting in increased capabilities compared to single-axis machines.

- Increased efficiency: Multi-axis NC lathes can be more efficient than single-axis machines for complex parts, as they can perform multiple operations in one setup.

- Improved accuracy: Multi-axis NC lathes have more advanced control systems, resulting in improved accuracy compared to single-axis machines.

Disadvantages:

- Higher cost: Multi-axis NC lathes are typically more expensive than single-axis machines, making them less accessible to small-scale operations and hobbyists.

- More complex to operate: Multi-axis NC lathes have multiple axes of motion, making them more complex to operate and maintain compared to single-axis machines.

Overall,multi-axis CNC lathes offer numerous benefits to manufacturers, including increased precision, versatility, and efficiency. Whether you’re a small workshop or a large production facility, a multi-axis CNC lathe can help you maximize productivity and profitability.

In conclusion, the choice between a single-axis and multi-axis NC lathe depends on the specific needs of your machining operations. If you require a machine for simple turning operations and cost is a concern, a single-axis NC lathe may be a suitable option. However, if you require a machine for more advanced turning operations and greater capabilities, a multi-axis NC lathe may be a better choice. It is important to consider the size and complexity of your parts, as well as your budget and experience level, when making your decision.