Types of Helical Gears

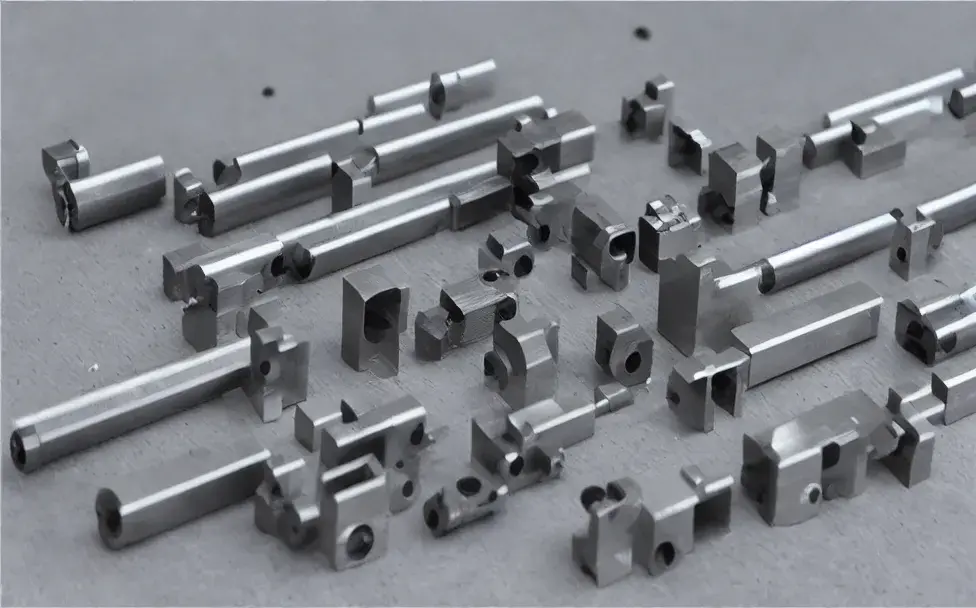

We offer a range of gear products, including:

Single Helical Gear: This gear has teeth that are cut at an angle to the gear’s axis and can transmit power in one direction.

Double Helical Gear: This gear has teeth that are cut at an angle to the gear’s axis and can transmit power in both directions.

Herringbone Gear: This gear has a unique V-shaped design that allows for smoother, quieter operation.

Crossed Helical Gear: This gear has two gears that are cut at an angle to each other, allowing for power to be transmitted between gears at different angles.

Helical Rack & Pinion: This gear has a straight rack that meshes with a helical pinion, providing a smooth transfer of power.

At our company, we specialize in manufacturing high-quality helical gears using the latest equipment and technology. We have invested in top-of-the-line gear manufacturing equipment, including gear hobbing and gear milling machines, to produce gears with the highest level of precision and accuracy.

Our Manufacturing Capabilities

We offer a range of gear manufacturing services, including gear hobbing and gear milling. Our gear hobbing machines are capable of producing single and double helical gears, herringbone gears, and crossed helical gears. These gears are ideal for applications that require high precision, durability, and quiet operation.

Our gear milling machines are capable of producing helical racks and pinions, which are used in a wide range of industrial applications. We can produce helical racks and pinions in a variety of materials, including steel, brass, and bronze, and with a range of tooth profiles and dimensions.

Services We Offer

At our company, we offer a range of helical gear manufacturing services, including:

Custom Gear Design and Manufacturing: We work closely with our clients to design and manufacture helical gears that meet their specific requirements. Our team of experts uses advanced CAD/CAM software to create accurate and precise gear designs, ensuring that each gear is tailored to the unique needs of the application.

Gear Cutting and Finishing: We have a range of gear cutting and finishing capabilities to produce helical gears with tight tolerances and a smooth surface finish. Our gear cutting machines are capable of producing gears in a range of sizes, from small to large, and our finishing equipment ensures a high-quality surface finish.

Quality Control and Testing: We take quality control and testing seriously, and all of our helical gears undergo rigorous testing to ensure they meet the highest standards of quality and performance. We use advanced testing equipment to check the gear’s dimensional accuracy, tooth profile, surface finish, and other critical features.

Technical Support and Consulting: Our team of experts is available to provide technical support and consulting services to our clients. We work closely with our customers to ensure that their helical gears are optimized for their specific application, resulting in improved performance and efficiency.

At our company, we are committed to providing our customers with the highest quality helical gears and services. Our team of experts is dedicated to ensuring that each gear is designed and manufactured to meet the unique needs of the application, resulting in improved performance, efficiency, and durability. If you are in need of high-quality helical gears, contact us today to learn more about our products and services.