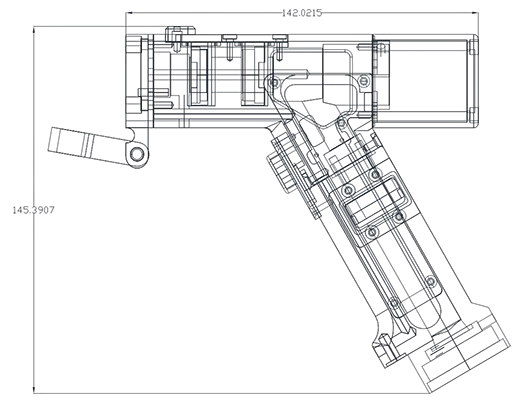

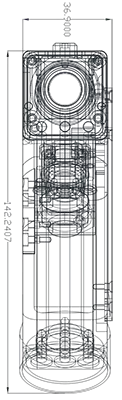

Handhold Welding Joint Laser Machine Parts

Equipped with a handhold welding joint, the high-power fiber laser welding machine is easy and flexible to operate. It is suitable for various metal materials such as stainless steel sheets, iron sheets, and galvanized sheets. It is especially suitable for complex and irregular welding processes and can perfectly replace traditional argon arc welding and electric welding.

PRICE ON REQUEST

Description

Handhold Welding Joint Feature

- The welding speed is fast, and the welding efficiency is higher than that of traditional welding. The operation is simple and can be welded

Workpieces at any position and at any angle. - It is suitable for welding small batches and multi-angle sheet metal and hardware parts.

- Equipped with a safety circuit to avoid false light and make the operation safer.

- The structure is compact and does not take up space.

- Small integrated design, ultra-long optical fiber transmission, overcomes the limitation of long-distance operation.

Processing Technology

| Laser Model | Continuous Laser |

| Fiber Connector | QBH Port |

| Laser Power | 1000W/1500W |

| Working Model | Continuous/Modulate |

| Indicating Light | Red Light |

| Weight | 0.943kg |

| Cooling Mode | Water Cooling |

Order Process

If you are interested in our product types/services, welcome to customize.

- Provide your drawings/samples

- Decomposition product process

- provide pricing

- Provide production control solutions

- Order raw materials

- start production

- full size inspection

- Delivery of your goods with inspection form

Read More Details Click Here!