Content Navigator

What is Gear Box?

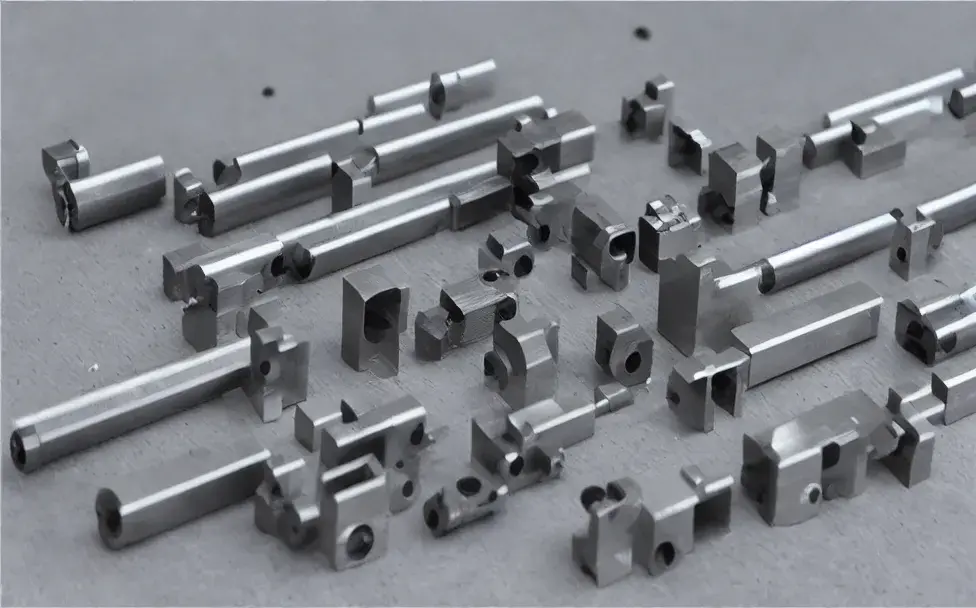

A gearbox is a power transmission mechanism that converts the number of revolutions of the motor to the desired number of revolutions and can change the torque. It consists of two or more gears, one of which is driven by a motor. The output speed of the gearbox is inversely proportional to the gear ratio. Gearboxes are generally preferred in constant speed applications, such as conveyors and cranes, where increased torque can be provided.

The gearbox consists of a driving gear with a certain diameter, another smaller gear (if the driving speed of the driven mechanism is higher than that of the driving mechanism) connected to the driving mechanism (electric motor, wind generator, diesel engine, etc.) (If the speed of the driven mechanism should be less than that of the driving mechanism) Connected to the mechanical load being driven. Just a speed/torque increase/decrease or vice versa mechanism

Among the mechanisms currently used to transmit power and motion, gearboxes are used in a wide range of applications. It can be seen in almost all kinds of mechanical transmission systems, from ships, automobiles, locomotives, heavy machinery for construction, processing machines and automated production equipment used in the machinery industry, to common in daily life. Household appliances, clocks, etc. Its applications range from large power transmission to small loads, and precise angle transmission can be seen in the application of gearboxes. Therefore, it is widely used in speed and torque conversion equipment.

What is the type of gearbox?

Gear boxes are essential components in many machines. From cars and bicycles to industrial machinery, gear boxes play an important role in helping these machines function efficiently. Different types of gear boxes meet the needs of different applications, so it’s important to understand the different types available.

—Classified by gear shape

-

- Gear Gearbox

- Spur gear gearbox

- Bevel Gearbox

- Conical – Cylindrical Gearboxes

- Worm Gearbox

- Cylindrical Worm Gearbox

- Arc tooth worm gearbox

- Bevel Worm Gearbox

- Worm – gear gearbox

- Planetary Gearbox

- Involute Planetary Gearbox

- Cycloid Gearbox

- Harmonic gear gearbox

- Gear Gearbox

—Classified by the number of shifts

1#Single-stage cylindrical gear reducer

2# Expanded bipolar cylindrical gear reducer

3# Expanded three-pole cylindrical gear reducer

4# Single-stage bevel gear reducer

5# Split type bipolar cylindrical gear reducer

6# Split type three-pole cylindrical gear reducer

7# Coaxial bipolar cylindrical gear reducer

8# Split type bipolar cylindrical gear reducer

9# Two-pole conical-cylindrical gear reducer

What are the advantages of the gearbox?

- 1# Wide selection of gear boxes

- The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the needs of users, and it can be transformed into an industry-specific gearbox. In the design of the gearbox, parallel shafts, vertical shafts, universal boxes and various components can be changed according to user requirements.

- 2# The operation of the gearbox is stable

- The operation of the gearbox is stable and reliable, and the transmission power is high. The outer box structure of the gearbox can be made of sound-absorbing material to reduce the noise generated during the working process of the gearbox. The box structure of the gearbox itself and the large fan can effectively reduce the working temperature of the gearbox. In the process of using the gearbox, it is necessary to timely clean the main gearbox. The gearbox cleaning machine uses the original oil supply and discharge system of the gearbox and the filtered lubricating oil to clean the gearbox without changing any hardware facilities of the gearbox or adding any cleaning agent, which ensures the safe operation of the gearbox and prolongs the service life of the gearbox. box life.

- 3# The gearbox has complete functions

- In addition to the deceleration function, the gearbox also has the function of changing the transmission direction and transmission torque. For example, after the gearbox adopts two sector gears, it can transmit the force vertically to another rotating shaft to realize the change of the transmission direction, while the gearbox changes The principle of transmission torque is that under the same power condition, the faster the gear rotates, the smaller the torque on the shaft, and vice versa.

what is a Gearbox used for?

The gearbox, also known as the gearbox, is a power transmission mechanism and a reduction transmission device; the gearbox converts the number of revolutions of the motor into the number of revolutions required by the working equipment through the meshing of gears with different numbers of teeth, and increases the torque installation.The gearbox mainly has the following functions:

- Acceleration and deceleration are often referred to as variable speed gearboxes.

- Change the transmission direction. For example, we use two sector gears to transmit the force vertically to another rotating shaft.

- Change the rotational torque. Under the same power condition, the faster the gear rotates, the smaller the torque on the shaft, and vice versa.

- Clutch function: We can achieve the purpose of separating the engine from the load by separating the two originally meshed gears. Such as brake clutch etc.

- Distribution of power. For example, we can use one engine to drive multiple slave shafts through the main shaft of the gearbox, so as to realize the function of one engine driving multiple loads.

How to Choose a Gearbox ?

Choosing the right gear box for your application is essential to achieving greater efficiency. With so many types and models available on the market today, it can be difficult to know which one is best for you. When selecting a gear box, there are several factors that must be taken into consideration.

First and foremost, you should evaluate the power requirements of your equipment. This will help determine what type of gear box is suitable for the job- whether it be a planetary, helical or spur gearbox. You should also assess any environmental considerations such as temperature, dust or moisture levels in order to choose an appropriate material grade for construction purposes. Additionally, consider any safety aspects such as noise level or speed control that may need to comply with local regulations and standards.