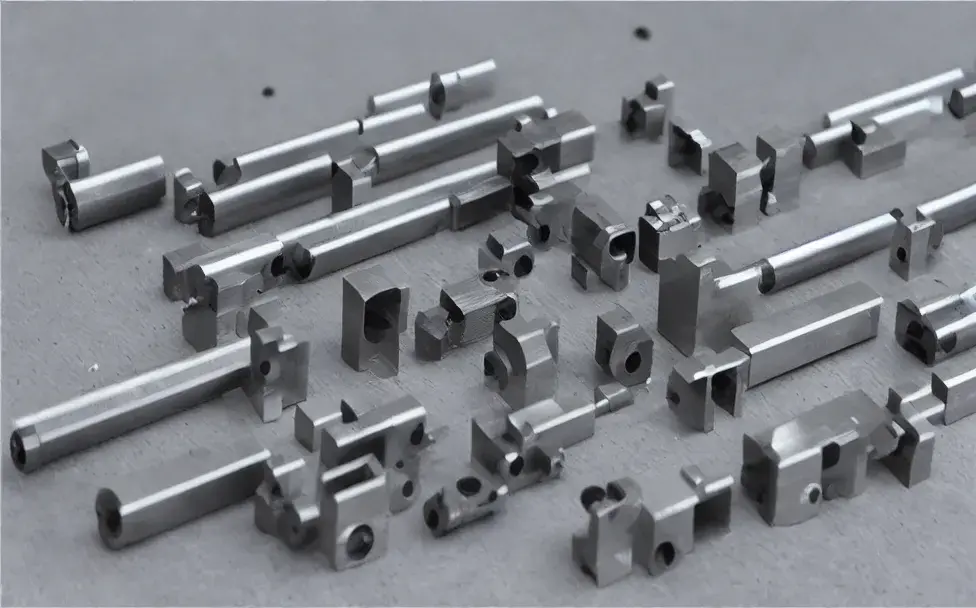

When it comes to fasteners in cnc machining, there are several options available for different applications. Each of these fasteners has its unique features and applications. In this article, we will take a closer look at these four fasteners and compare and contrast their differences. By the end of this article, you’ll have a better understanding of which fastener to choose for your specific needs.

Overview of Bolt, Screw, Rivet, and Nut

Bolt:

Bolts are threaded fasteners that require a nut to secure objects in place. They are often used for heavy-duty applications, such as construction and engineering, due to their strength and durability.

Screw:

Screws are similar to bolts but are self-tapping, which means they can create their own threads as they are driven into materials. They are commonly used in woodworking, electronics, and other applications where the material is too thin for a bolt.

Rivet:

Rivets are non-threaded fasteners that use a process called riveting to join two materials together. This process involves pulling the mandrel through the rivet, which creates a permanent and secure bond. Rivets are often used in aircraft, automobiles, and other applications where vibration and movement are present.

Nut:

Nuts are typically used in conjunction with bolts to secure objects in place. They are designed to fit the thread of the bolt and create a secure connection. Nuts are often used in construction, automotive, and other applications that require high strength and load-bearing capacity.

Comparing and Contrasting:

When choosing between bolts, screws, rivets, and nuts, it is essential to consider the application and the specific features of each fastener.

Strength and Durability:

Bolts are the strongest of the four fasteners and can handle higher loads and stresses. Screws have less strength but are still suitable for many applications, especially in materials where a bolt may strip the threads. Rivets can also handle high loads but have limited use due to the process of installing and removing them. Nuts are designed to complement bolts, and the strength of the connection is dependent on the strength of the bolt.

Installation and Removal:

Bolts and nuts are easy to install and remove, making them suitable for applications where adjustments may be necessary. Screws are also easy to install and remove, but they may strip the threads in softer materials. Rivets are permanent and challenging to remove, making them suitable for applications where the bond needs to be permanent.

Materials:

Bolts, screws, and nuts are suitable for a wide range of materials, including metals, plastics, and composites. Rivets are best suited for materials that cannot be drilled, welded, or soldered, such as ceramics or glass.

Cost:

Bolts, screws, and nuts are generally less expensive than rivets due to the process of installing and removing them. Rivets require specialized tools and equipment, which increases the overall cost.

In summary, bolts, screws, rivets, and nuts are essential fasteners in various industries. Each fastener has unique features and applications that make them suitable for different types of projects. When choosing between these fasteners, it is important to consider the application and specific features to ensure the best results.