Chii chinonzi Knurling?

Knurling inzira yekugadzira simbi inosanganisira kugadzira pateni yediki, yakaita sedhaimondi pamusoro pechishandiso. Maitiro acho anowanzo itwa nekutsikirira mudziyo wekurovera uchipokana neworkpiece, zvichiita kuti simbi iparare uye igadzire patani yakaita sedhaimani. Mitsetse inoguma inopa kubata kuri nani kumushandisi, zvichiita kuti zvive nyore kubata uye kushandisa workpiece.(Read more nezve cnc kushandura zvigadzirwa mushure mekucheka)

Knurling inogona kuitwa pazvinhu zvakasiyana, zvinosanganisira simbi sesimbi, ndarira, aluminium, uye mapurasitiki nezvimwe zvinhu. Maitiro acho anogona kuitwa nemaoko uchishandisa knurling chishandiso kana mushini wakasarudzika wakagadzirirwa chinangwa ichi.

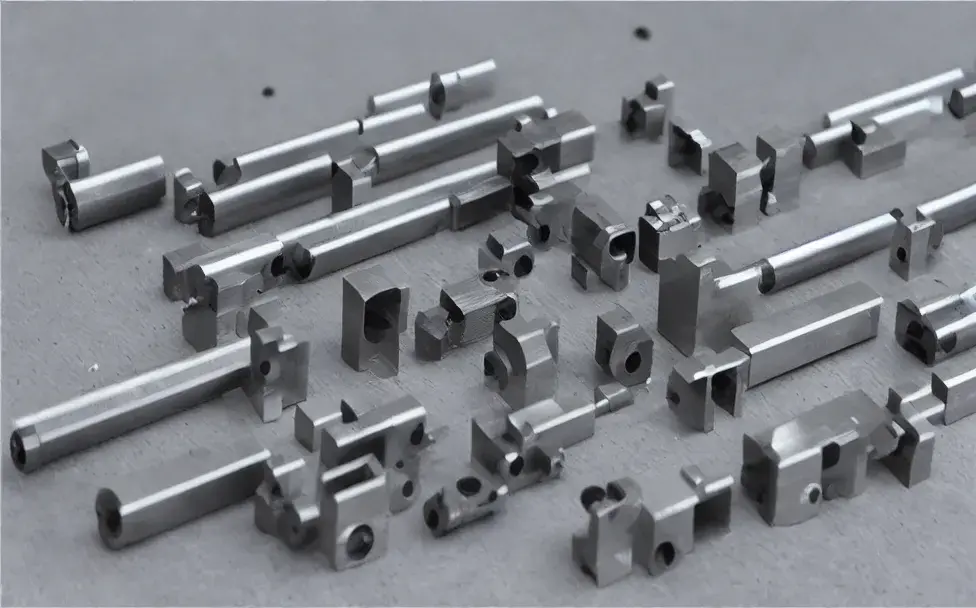

Chii chinonzi Knurling Tool - Mhando dzeKnurling Zvishandiso

A knurling turusi yakakosha kubatsira nekuita knurling. Chishandiso ichi chinowanzo kuve chine mubato, vhiri rinomonereka, uye chibatiso. Gumbo rekukwidibira chikamu chechishandiso chinosangana nechokushandisa uye chinogadzira dhaimondi-yakaita patani.

Zvishandiso zveKnurling zvinouya muhukuru hwakasiyana uye maumbirwo, zvichienderana nechaiyo application. Zvimwe zvishandiso zvakagadzirirwa zvidiki zvekushanda, nepo zvimwe zvakagadzirirwa makuru. Zvichienderana nechimiro chaunoda, vhiri rekurovera rinogonawo kusiyana muhukuru uye chimiro.

Mhando dzinoverengeka dzematurusi ekushandisa anowanikwa kuti ashandiswe, imwe neimwe iine chaiwo maapplication uye zvakanakira. Mamwe emhando dzakajairika anosanganisira:

Straight Knurling Zvishandiso: Aya ndiwo anonyanya kuzivikanwa emhando ye knurling chishandiso chinoshandiswa kugadzira yakatwasuka knurl mapatani. Iwo anowanikwa muhukuru hwakasiyana uye magadzirirwo kuti aenderane akasiyana workpiece saizi uye zvinhu.

Diamond Knurling Zvishandiso: Dhaimondi knurling maturusi anogadzira mapatani akaita sedhaimani pane workpiece. Maturusi aya anowanzo shandiswa kune maapplication ane zviri nani kubata, senge pamaturusi kana zvibato.

Involute Knurling Tools: Involute knurling zvishandiso gadzira yakatenderedzwa knurl pateni. Rudzi urwu rwepateni runowanzo shandiswa mumashandisirwo apo inodiwa yakapfava, yakatenderedzwa kubata, senge pamapfundo kana mamwe magadzirirwo eergonomic.

Push Knurling Zvishandiso: Push knurling maturusi anoshandiswa nemaoko uye anoshandiswa kune madiki ebasa. Aya maturusi akareruka anoda kushomeka kuseta, achiaita akanakira madiki-adiki knurling application.

Dhonza Knurling Zvishandiso: Dhonza maturusi ekushandisa anoshandiswa kune akakura maworkpiece uye anowanzo shandiswa nelathe kana mamwe machina. Vanoda kuseta kwakaomarara asi vanogona kuburitsa nzvimbo dzakakura dzakafukidzwa nekukurumidza uye nemazvo.

Kuita Knurling paLathe

Knurling on lathe inzira inosanganisira kushandisa knurling tool kugadzira pateni yediki, yakaita sedhaimani ridges pamusoro pecylindrical workpiece. Iyo nzira inosanganisira matanho anotevera:

- Gadzirisa lathe, chengetedza workpiece, uye gadzirisa uye pakati payo.

- Sarudza chakakodzera knurling chishandiso basa racho.

- Isa chigadziro mumudziyo wekushandisa uye pane workpiece.

- Tanga lathe, fambisa chishandiso kuti ubatane neworkpiece, uye shandisa muchinjiko slide uye kuzorora kwekomboni kudzora kudzika kwekucheka.

- Fambisa chishandiso pamwe nekureba kwechishandiso kuti ugadzire inoenderera pateni yemadiki, madhaimondi-akaita ridge.

- Ongorora nzvimbo yakavharwa kuti ichokwadi uye hunhu, uye ita chero shanduko dzinodiwa kuti uwane mhedzisiro yaunoda.

Knurling inzira yakakosha yesimbi inogona kupa zvirinani kubata uye usability kune akasiyana workpieces. Ingave yakaitwa nemaoko kana nerubatsiro rwechishandiso chakasarudzika, maitiro acho anoda kunyatsotarisisa kune zvakadzama uye kuseta kwakaringana kuti uwane mhedzisiro yaunoda. Nekunzwisisa mhando dzakasiyana dzematurusi ekugadzira uye matekiniki aripo uye maitiro ekuita knurling pane lathe, unogona nekuvimba kusimudzira hunyanzvi hwako hwekugadzira simbi uye kutora mapurojekiti akawanda.