What is Knurling?

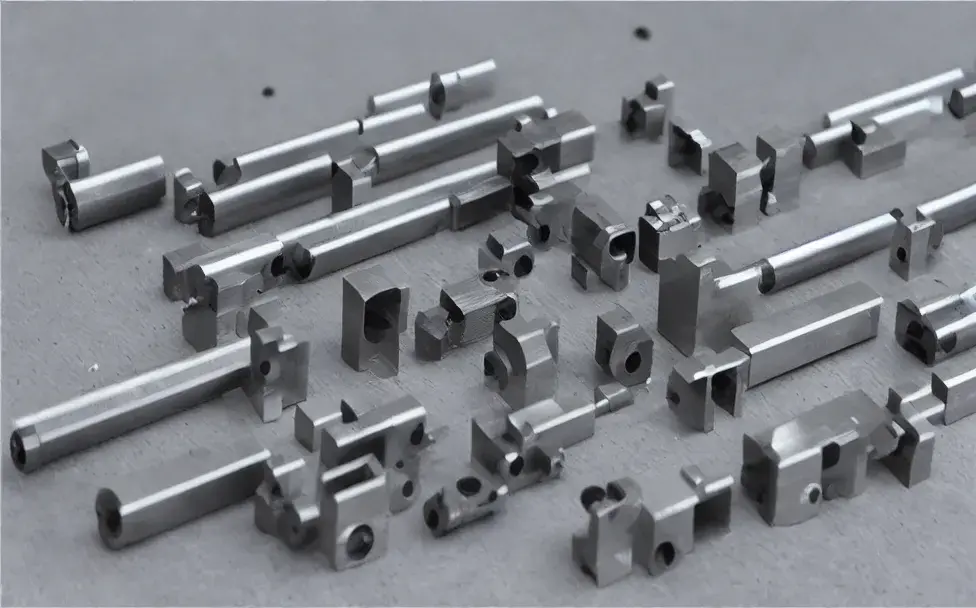

Knurling is a metalworking process that involves creating a pattern of small, diamond-shaped ridges on the surface of a workpiece. The process is typically done by pressing a knurling tool against the workpiece, causing the metal to deform and form a diamond-shaped pattern. The resulting ridges provide a better grip for the user, making it easier to hold and use the workpiece.(heluhelu hou about cnc turning products after knurling)

Knurling can be done on various materials, including metals such as steel, brass, aluminum, and plastics and other materials. The process can be done manually using a knurling tool or a specialized machine designed for this purpose.

What is a Knurling Tool – Types of Knurling Tools

A knurling tool is specialized to help with the knurling process. The tool typically consists of a handle, a knurling wheel, and a holder. The knurling wheel is part of the tool that comes into contact with the workpiece and creates a diamond-shaped pattern.

Knurling tools come in various sizes and shapes, depending on the specific application. Some tools are designed for small workpieces, while others are designed for larger ones. Depending on the desired pattern, the knurling wheel can also vary in size and shape.

Several types of knurling tools are available for use, each with specific applications and advantages. Some of the most common types include:

Straight Knurling Tools: These are the most common type of knurling tool used for creating straight knurl patterns. They are available in various sizes and configurations to suit different workpiece sizes and materials.

Diamond Knurling Tools: Diamond knurling tools create diamond-shaped patterns on the workpiece. These tools are typically used for applications with a better grip, such as on tools or handles.

Involute Knurling Tools: Involute knurling tools create a rounded knurl pattern. This type of pattern is often used in applications where a smoother, more rounded grip is desired, such as on knobs or other ergonomic designs.

Push Knurling Tools: Push knurling tools are operated manually and are used for smaller workpieces. These simple tools require minimal setup, making them ideal for small-scale knurling applications.

Pull Knurling Tools: Pull knurling tools are used for larger workpieces and are typically operated with a lathe or other machinery. They require a more complex setup but can produce larger knurled surfaces more quickly and efficiently.

Performing Knurling on a Lathe

Knurling on a lathe is a process that involves using a knurling tool to create a pattern of small, diamond-shaped ridges on the surface of a cylindrical workpiece. The process involves the following steps:

- Set up the lathe, secure the workpiece, and align and center it.

- Choose an appropriate knurling tool for the job.

- Position the tool in the tool holder and on the workpiece.

- Start the lathe, move the tool into contact with the workpiece, and use the cross slide and compound rest to control the depth of the cut.

- Move the tool along the length of the workpiece to create a continuous pattern of small, diamond-shaped ridges.

- Inspect the knurled surface for accuracy and quality, and make any necessary adjustments to achieve desired results.

Knurling is an important metalworking process that can provide better grip and usability for various workpieces. Whether done manually or with the help of a specialized tool, the process requires careful attention to detail and proper setup to achieve the desired results. By understanding the different types of knurling tools and techniques available and how to perform knurling on a lathe, you can confidently enhance your metalworking skills and take on a wider range of projects.